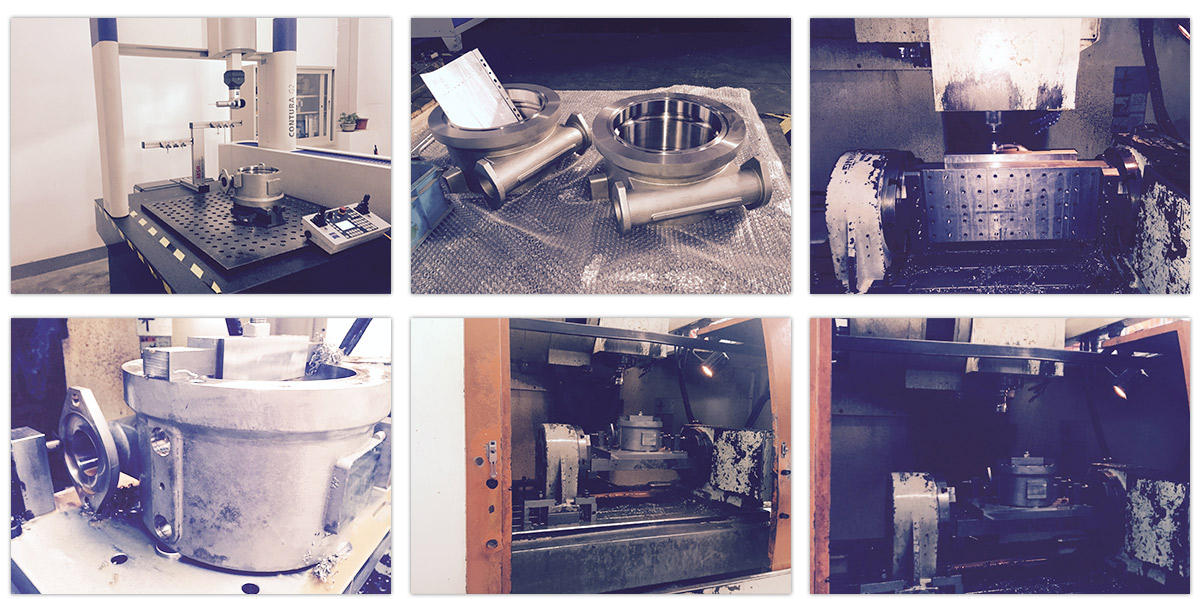

Precision CNC Turning & Milling of Gearbox Housing

At HLF, we understand the importance of providing the complete solution to our customers manufacturing needs. The gearbox housings manufactured for marine industry is just one example of how our core machining capabilities, backed by our diverse value-added services has earned us a reputation for achieving project objectives as quickly and efficiently as possible.

The gearbox housing was machined from 316 stainless steel casting. The primary operations involved investment casting, precision turning of ID and facing, internal grooving, and drilling and tapping of internal threads.

Careful inspection of the bore diameter, inner ball groove, and position accuracy with CMM, ensured we satisfied the precise +/-.002" dimensional tolerance requirements. We packaged each of unit in this order according to the customer's guidelines to protect them during shipping to ensure that they arrived safely at their destination.

To learn more about this project, or how we can put our manufacturing expertise to work for you, please see the chart below or contact us today.

Highlights of Custom Machining of Gearbox Housing

| Product Name | Stainless Steel Gearbox Housing |

| Product Description | Gearbox Housing |

| Capabilities Applied/Processes | Primary: Investment Casting CNC Turning CNC Milling Drilling/Tapping Secondary: Packaging/Shipping |

| Equipment Used to Manufacture Part | Horizontal Turning Center, Vertical Milling Center with 4th axis |

| Overall Part Dimensions | 12" x 13.5" x 9.6" |

| Tightest Tolerances | +.002" |

| Material Used | 316 Stainless Steel |

| In process testing/inspection performed | Dimensional and Visual Inspection |

| Volume | 100 units |

| Delivery Location | USA |

| Standards Met | Customer Specifications, 2D CAD Drawing |